Organizations that are applying Lean Thinking to achieve the greatest improvements in speed, efficiency and profitability share a common characteristic. Each one fully utilizes the knowledge, skills and enthusiasm of people at all levels.

Lean Belt Certification

Training is Critical for Successful Lean Performance

Lean Belt Graduation

Watch a couple of our client’s employees receive certification

Learn more about the Lean Belt Certification

Any manager concerned with increasing customer satisfaction by reducing costs, improving quality, and providing faster delivery must learn to manage by cycle time. From this succinct; highly focused book, you’ll learn what CTM is, how to implement it quickly throughout your organization, and how to manage it. Case studies, over 40 illustrations, and straightforward language make this a book you can use to enlighten your entire work force.

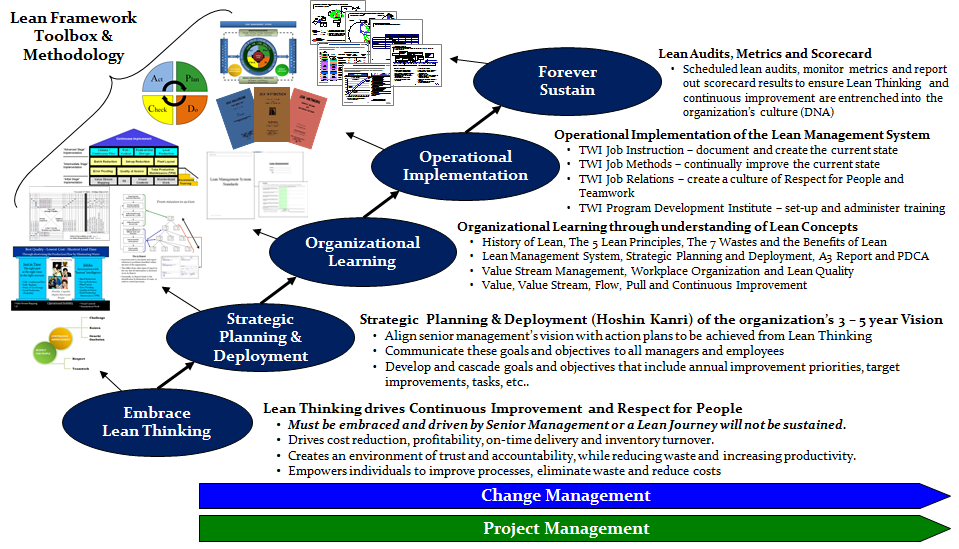

Lean Framework Introduction

The Pathway to Excellence

The Lean Framework is the “Pathway to Success” for companies wishing to begin, to continue or to re-start their Lean Journey. The key to successful implementation of lean manufacturing must be the total commitment on the part of every employee in an organization to make it work. By that we mean: all levels of the organization, from employees to supervisors to managers to the senior management, must be aware of the fundamentals of lean and must make their best efforts to practice and improve them day-by-day.

The key to successful implementation of lean manufacturing must be the total commitment

A critical reason lean journeys fail is that organizations try to implement individual elements instead of the entire Lean Manufacturing approach. Since the elements of Lean Manufacturing are integrated and interdependent, any attempt to implement Lean Manufacturing only partially will produce very sub-standard results. For Lean Manufacturing to work effectively, it needs to be adopted in its entirety, not piecemeal. It is the totality of the elements and the synchronized relationship to one another that make them most effective.

CTM has implemented the Lean Framework to numerous clients over the past four decades with tremendous results

We have implemented the Lean Framework to numerous clients over the past 4 decades with tremendous results. We have built several case studies to illustrate the effects that the framework can have when implemented correctly. You can read through these case studies in the benefits pages: “Increase Profits”, “Minimize Costs”, “Maximize Productivity”, “Optimize Efficiency”. For more information contact us directly.

Lean Simulation for Smart Investment

Simulation is a proven proactive tool for proper decision-making and complex comparative analysis. With simulation, organizations gain the ability to cost-justify their decisions to make process improvements. Along with Lean activities, advanced simulation is an economical tool that helps you understand change within your processes and visualize both changes and the resulting costs prior to implementation.

With simulation, organizations gain the ability to cost-justify their decisions to make process improvements.

CTMs multidisciplinary team draws on the experience of specialists in technology, Lean process engineering and specific industry verticals to develop highly accurate, carefully validated simulation models. Relying on a world-class analysis methodology, CTMs simulation modeling tool enables us to:

- Model complex systems that mirror your current state to accurately measure the impact of proposed operational changes

- Establish quantifiable baseline measures related to your operational capacity

- Assess the effect of new conditions on key metrics, such as the impact of staffing changes on productivity or the impact of automating manual processes on costs

- Identify process bottlenecks to prioritize action items

- Develop detailed reports that can be exported to other tools for further analysis

- Identify the key cost contributors to each of your processes to support Lean business case development and provide insight into the payback equation

- Visually display how changes to specific variables will affect organizational output

- Predict the success or failure of operational changes down to a specific percentage of probability

Learn what we can do for you!

Industry Leader

CTM has developed a comprehensive process (The Lean Framework) that allows an organization to create an environment and a means for change. Change that permeates the entire company and becomes a new paradigm for growth.

Learn MoreIncrease Profits

CTM's Lean Framework sets out clear-cut objectives that can be achieved through an ongoing process of cycle time reduction and continuous improvement. This process has had tremendous results consistently.

Learn MoreOptimize Efficiency

Moving from reactive to proactive thinking in the work place. Having the employees understand the importance, scope and techniques involved allowed many clients to move forward at greatly accelerated rates.

Learn MoreMinimize Costs

CTM focuses on five key issues: identifying waste, cellular production, scheduling, production line processes, and production line support. Our process helps firms eliminate all inefficiencies and thrive.

Learn MoreMaximize Productivity

Clients have found CTM’s Lean Assessment approach of key employee interviews, financial review, facility visit and a lean manufacturing evaluation to determining lean implementation requirements has been very effective.

Learn MoreProven Experience

CTM was incorporated in 1986 and has delivered high quality services to numerous organizations in manufacturing, healthcare, and other industries. Read our clients' success stories.

Learn More