How To apply 5s One of the Key Lean Tools in Your Operation

This course provides you with an understanding of the theory and most effective way to apply 5s concepts, principles, and tools with a focus on identifying and eliminating waste, improving process flow, continuous improvement, and flexibility to achieve optimal performance. Understanding the 5s was developed by Toyota and how and when 5s needs to be applied to achieve a successful Lean implementation is critical.

What does 5S mean?

The 5S system is a way of focusing and thinking in order to better organize and manage a workspace, with the goal of increasing productivity and profits. It is one of the elements within the Lean Methodology, a process that encompasses several elements to take the traditional operation and streamlining the environment in a way that maximizes productivity, and hence improves profits.

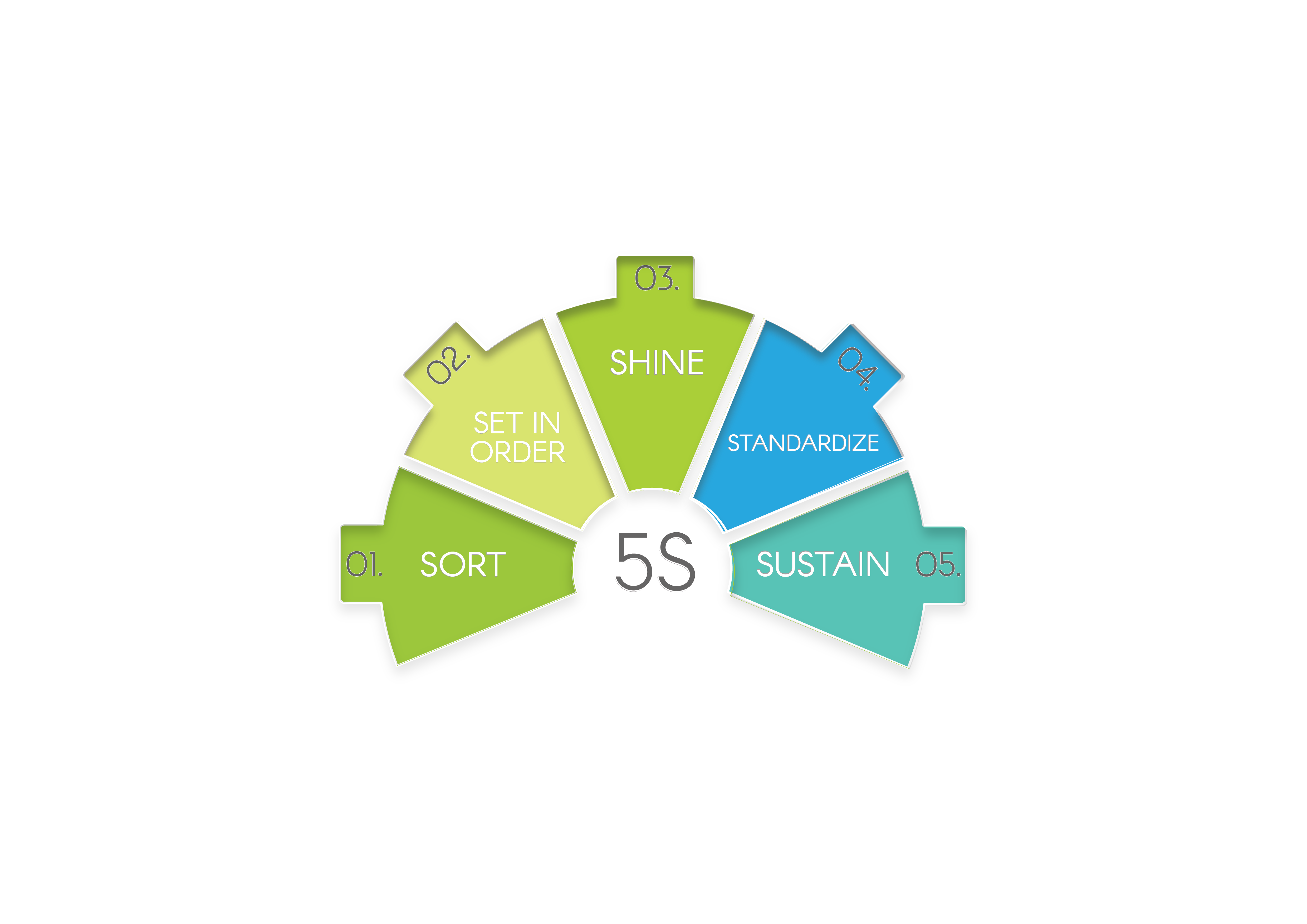

What does each S stand for in 5S?

The 5S’s stand for sort, straighten, shine, standardize, and sustain. Sort is the first step, and it involves categorizing all the items in the production process based on how much, when, and where they are needed. This is done through a “Red Tag” process. During the “Straighten” step, the focus is to develop a system of organization, which makes it obvious where everything belongs. The third step in the process, “Shine”, involves establishing a process that ensures the upkeep of the production area on a continuous basis. Once the first three steps are in place, the next goal is to “Standardize” these new practices to ensure that they become the new norm for the workspace. Once these standards are implemented, the old habits will soon be eliminated and replaced by more efficient methods of production. The final step of the 5S system, “Sustain”, requires the most discipline, in order to ensure that the positive steps taken towards increased productivity to indeed become the new way of doing things.

What does 5S Training consist of?

Because 5S is just one of several elements that make up the Lean Methodology, it is usually done as part of the Lean Belt Certification Training. Our focus is to educate our customers and deliver on their unique needs, so if the 5S training is the only interest of your organization, our program will be customized to do exactly that. If the goal is to improve production, then Lean Training is more comprehensive. Organizations that are applying Lean Thinking to achieve the greatest improvements in speed, efficiency and profitability share a common characteristic: each one fully utilizes the knowledge, skills and enthusiasm of people at all levels. There are several approaches to implementing the Lean elements.

- 5S Training

- Holistic Lean Training

- Custom Lean Training

- Online Lean Training

What industries can 5S be applied to?

That’s a good question. In the beginning, when I started the company, it was hard enough to get manufacturers interested because there was the “It won’t work here in America, or in Canada” idea. We’ve learned over the years that 5S, one the principles of lean, works in any industry, any office, any type of business. We’ve worked in with success in healthcare, wineries, the food industry, insurance companies, and many other industries.

- Manufacturing

- Management

- Business

- Health Industry

- Legal System

- Government

What is lean?

There is not one agreed upon definition of lean. In the eyes of different education and consulting groups, it can be different things. A problem is the lack of a Lean Standard, as there is with quality (ISO Standard). It’s made up of many subsections, like the Total Productive Maintenance, Quick Change, Containerization, Pull System, Error Proofing, 5S, many more elements. It can be quite overwhelming to an organization that’s first looking at it and trying to figure out how to implement it in their company.

What it boils down to is the process. It’s about taking your traditional operation and trying to streamline the environment: that’s the factory floor and the office, the whole company.

What is the main approach?

Because there is no Lean Standard in the world, it’s up to each company that’s training and educating people on lean to interpret the Toyota Production System on their own. Hence, some of them get it right and some of them don’t. There are many approaches, but it encompasses the journey from traditional methodology to lean production, while looking at the entire enterprise holistically. We did this when we started in 1986, while most have only started looking beyond the factory in the last ten years, since around 2007. Most consulting groups, when they come in to try and help a firm with improvements, they look at the organization how it’s structured (Vertically) not how the processes run from end to end (Horizontally). We started doing this since the 80’s and its just one of the elements that we consider.

What are some lean tools and techniques?

Well, it boils down to probably 4 or 5 different elements. One is trying to determine what value is in your process. The activities of workers as they are operating in the office or in the factory can be either categorized as: essential activities, or non-essential that shouldn’t be there. Today, they call this value-added and non-value-added. The value is one thing that they must look at very hard. Another element is value streaming. What do you need to do? There are some core value streams in your business, what we call the Make Ship loop, and there’s the supply chain loop in the business. Understanding what the high-level value streams are and then breaking the company down into core value streams and sub-value streams helps you start to understand the flow. You can then identify whether it’s good, bad, or where the bottlenecks are, and the whole issue of scheduling. We talk about pull scheduling when we’re talking about lean. Traditional manufacturers tend to push goods through the organization, and we help companies change to pull things through the factory, as opposed to pushing them. So, that’s another important element.

What are common issues when implementing lean?

There can be a number of issues. Starting at the top, senior management needs to do much more that to simply support the program. In our experience, it’s way more than that. To do a successful implementation and transfer of operating methods, we need a senior management that can teach lean. They need to be engaged, and the way they lead is by using some of the new tools that are out there that Toyota uses, like Hoshin Planning. By doing that, and doing it properly, the senior management now has a role to drive what needs to be changed in the business and to pass that down level by level. They must communicate very well with the entire workforce.

The people in each company is your biggest variability and can cause different concerns. Obviously, you want people to participate, but if you don’t have leadership at the top, the people will do whatever they want. I think inherently people want to improve their business, but they’re nervous. If you have a management team and go in a company that has not worked in teams, people are generally going to be afraid to participate in anything new, and think “Well, this is another case where the President got off an airplane, read a book and it’s the project of the month”. You’ve got to get past all of that, and the best way you can is with a good level of education. Personally, I don’t understand how a president of a company can tell the workforce we want to do lean and not give them the tools or the knowledge necessary. Remember, they might have been working there 20 years using the traditional methodology and they don’t know the difference between a streamlined process and what they’re currently doing. So, you may end up digging the same hole deeper and expecting better results without the proper training.

Communication can also be a problem if everything is not set up properly. Lack of project management, not providing the necessary resources, there are many things that can get in the way.

- View a list of our clients

- Learn the steps we take to combat these issues directly from our team of educators

How is CTM an industry leader in lean training?

We’ve helped companies, many of them, implement lean operating practices over the last 35 years, so we have a very good position and understanding of what it takes to implement the lean techniques and change from traditional processes. We have also developed a through set of criteria to help standardize lean training to ensure that it is done properly.

What experience does CTM have with lean?

One thing you can be sure of. The CTM Program Directors “have been there and they have done it before”. These professionals are true practitioners. They spend the vast majority of their time, and their careers, in the field and on the job, learning and perfecting their craft. For them, it is an ongoing task, and no matter what they develop for the classroom and books, they know it only works when it is put into practice.

How does lean increase profits?

Cycle Time Management has helped companies increase pretax profits up to 27 fold. In the last three decades it has become clear that the elimination of waste, or non-value-added activity, has freed business to increase profit margins drastically. In the case of Mott Manufacturing, once the CTM evolution plan was successfully implemented, the firm experienced extraordinary increases in sales, which in turn generated greater profits.

How does lean optimize efficiency?

Treating people as a value adding asset in the process of business improvement is an essential CTM ingredient for success. It allows the people in the organization to take responsibility for the business process, which generates a continuous improvement mentality and empowers the whole organization to assist in the decision making for future success!

How does lean maximize productivity?

- When Cycle Time Management’s Program Directors come to your company to custom-tailor your Learning Cycles Supervisor program, they will quickly zero in on the key issues. They will determine where you are at, what the barriers are, and then develop the appropriate workshop lessons and approach.

How does lean cut costs?

A key focus of Lean is on eliminating waste. We’re talking waste of overproduction, transportation, when a piece of equipment is sitting idle, people are sitting idle, motion (taking ten steps when you only need to take one if your operation were laid out differently), over-processing, inventory, and defects. All of those are various types of waste that are found in what we’ll call traditional organizations as opposed to somebody attempting to implement lean.

I still go into factories today that have a 20-ton press which takes 8 hours to do a changeover of a die on. A company that has implemented lean however, can do it in 10 minutes on an identical machine. So, there is quite a difference once you allow yourself the flexibility to shorten your runs and move more effectively.

What industries can lean be applied to?

That’s a good question. In the beginning, when I started the company, it was hard enough to get manufacturers interested because there was the “It won’t work here in America, or in Canada” idea. We’ve learned over the years that the principles of lean, being process oriented, work in any industry, any office, any type of business. We’ve worked in with success in healthcare. We have implemented lean in wineries, improving efficiency throughout the organization. We’ve also worked with great results in the food industry, insurance companies, and many other industries. In Canada, most companies are not as far ahead as in the States, but we’re on the verge of the insurance companies opening up in a big way to the whole lean experience.

- Manufacturing

- Management

- Business

- Health Industry

- Legal System

- Government

Learn 5S via Lean Belt Training

Learn more about the 5S Training

Introduction to 5S Training

The 5S system can lead to great increases in profits through the re-organization of a workplace. The objectives are to improve safety, productivity, quality, and efficiency. A time-driven approach brings order to the productivity improvement process. Instead of being overwhelmed by a large number of seemingly disjointed projects, you can integrate projects at a higher level and implement changes in a systematic way. Time becomes the overall productivity measure and integrates the improvement performance.

Cycle Time Management has implemented the 5S system as part of their Lean Training with great results across many industries

In any workplace, there are numerous sources of waste, which can be removed through effective organization. These include: defects, inventory, motion, non-value-added processes, overproduction, transportation, and waiting. By removing waste and developing standardized processes, you can achieve all the objectives previously mentioned and notice an improvement in your profit. Treating people as a value adding asset in the implementation of 5S is an essential CTM ingredient for success. This allows the people in the organization to take responsibility for the business process and the improvements, which is essential to generate a continuous improvement mentality and empower the whole organization to assist in the decision make for future success!

Learn what we can do for you!

Proven Experience

CTM was incorporated in 1986 and has delivered high quality services to numerous organizations in manufacturing, healthcare, and other industries. Read our clients' success stories.

Learn MoreIndustry Leader

CTM has developed a comprehensive process (The Lean Framework) that allows an organization to create an environment and a means for change. Change that permeates the entire company and becomes a new paradigm for growth.

Learn MoreOptimize Efficiency

Moving from reactive to proactive thinking in the work place. Having the employees understand the importance, scope and techniques involved allowed many clients to move forward at greatly accelerated rates.

Learn MoreMinimize Costs

CTM focuses on five key issues: identifying waste, cellular production, scheduling, production line processes, and production line support. Our process helps firms eliminate all inefficiencies and thrive.

Learn MoreServices

The right training is critical for successful lean performance. CTM will make sure your Lean Training works. See all the services that CTM's Lean Framework offers!

Learn MoreMaximize Productivity

Clients have found CTM’s Lean Assessment approach of key employee interviews, financial review, facility visit and a lean manufacturing evaluation to determining lean implementation requirements has been very effective.

Learn More